Efficacy of Piezoelectric Materials in Energy Generation

What are the Importance of Piezoelectric Materials?

Piezoelectric materials possess the ability to generate electrical energy by converting mechanical vibrations into electric fields.

Unlike batteries or other external power sources, they are a sustainable and renewable source of energy and have a much longer lifespan and low maintenance requirements.

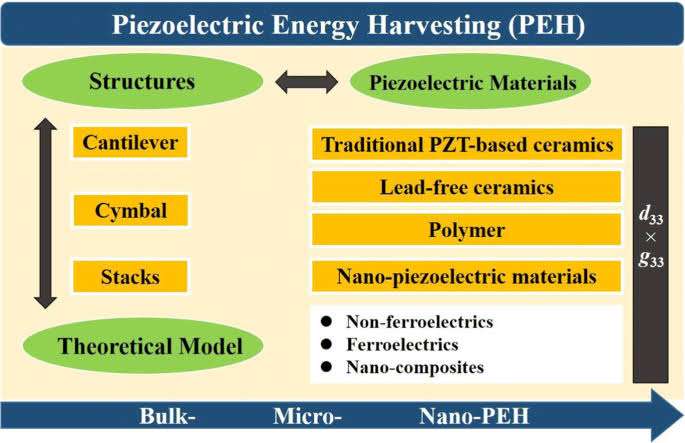

Piezoelectric energy harvesters are primarily composed of piezoelectric ceramics or polymers that contain piezoelectric elements but can be constructed with other materials as well.

Polymer-based composites and refractory metals have also been used in piezoelectric energy harvesters.

These materials are typically characterized by high specific piezoelectric coefficients and have good thermal conductivity.

The choice of material in a piezoelectric energy harvester depends on the desired performance characteristics and cost.

The most common piezoelectric materials used in energy harvesters are crystalline and ceramic-based.

Lead zirconate titanate (PZT) is one of the most commonly used materials for energy harvesting applications.

It has a high specific piezoelectric coefficient and a wide sintering temperature window.

Advantages of Piezoelectric Energy Harvesting

Piezoelectric energy harvesters can reduce environmental impact by utilizing ambient vibrations to generate electricity and eliminating the need for battery replacements.

PZT has been used in a variety of energy harvesting applications such as unimorph cantilever beams and MEMS accelerometers.

Researchers have developed various methods to improve the efficiency of piezoelectric energy harvesters.

One method is to incorporate metallic endcaps in the shape of a cymbal on both sides of the piezoelectric layer, which increases the mechanical stress that can be generated and improves its efficiency.

Another technique is to use an acoustic funnel, which converts mechanical vibrations into an acoustic wave that can be converted back into electric energy.

This method can be particularly effective in high-frequency applications such as acoustic waves and ultrasound.

Recently, researchers have begun to explore the potential of cellular polymer foam materials with piezoelectric-like responses for energy harvesting applications.

These materials, referred to as ferroelectric foam, consist of permanent electric charges stored in the internal voids of the structure.

They have been fabricated into several different configurations for energy harvesting, including stacked configurations.

It is important to note that the polarization direction and strain direction of these structures should be aligned with each other to maximize energy conversion efficiency.

Application of Piezoelectric energy harvesters

The versatility of piezoelectric materials enables a wide range of configurations to be used in energy harvesting applications.

The electrode pattern, poling direction, and strain direction can all be altered to achieve the desired configuration for a specific application.

The volume and layers of the piezoelectric material can also be modified to optimize its resonant frequency.

Piezoelectric energy harvesters can be used to collect vibrations from ambient sources and convert them into electricity.

They are often embedded into structures to power sensors and wireless monitoring systems.

This helps reduce battery replacement costs and environmental impact. These devices can also be integrated into wearable electronics to harvest energy from body movements and extend their battery life.

Another application of piezoelectric energy harvesters is the ability to capture power from ocean water currents.

This is achieved by using a flow-induced vibration to produce electricity. Two significant types of flow-induced vibration are Vortex-Induced Vibrations (VIV) and Self-Excited Vibrations (SEV).

VIV is created by a bluff body in a stream, which causes a series of vortices to form behind it.

The VIV can then be coupled to a piezoelectric energy harvester, which generates electricity by oscillating in response to the induced voltages.

SEV is generated by a mass-loaded bluff body, which can also be coupled to a piezoelectric system to generate electricity.

While monolithic piezoceramics have high coupling coefficients, they cannot be shaped or conformed to curved surfaces and are brittle and dense.

To overcome these limitations, researchers have developed composite piezoelectric energy harvesters that combine an active piezoceramic phase with a polymer matrix phase.

This combination offers improved flexibility and robustness while increasing the energy harvesting efficiency.

The most common piezoelectric energy harvester structure consists of a cantilever beam with one or two piezoelectric layers.

A cantilever beam with one layer of piezoelectric material is referred to as an unimorph, and a cantilever beam with two layers is called a bimorph.

The bimorph structure is more efficient than the unimorph, as it produces higher output power at a wider range of operating frequencies.