Applications of Additive Manufacturing in various Fields

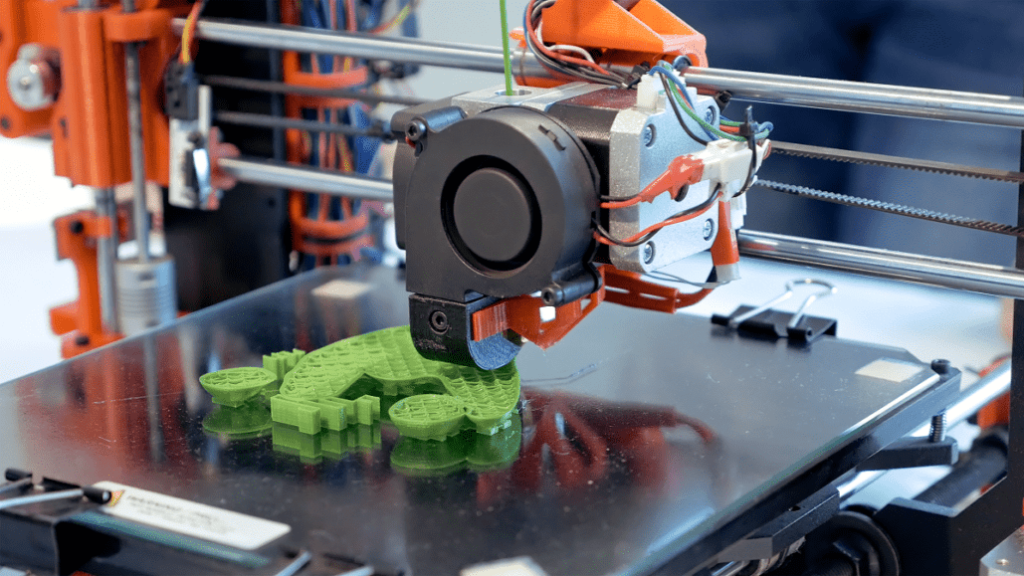

3-Dimensional printing is not a new technology that is used to produce prototypes. However, this technology is still evolving and additive manufacturing is now used across different industries.

3D printing and additive manufacturing applications help companies to manage their resources such as time, materials, personnel, and even money.

There are now several companies using 3D printing for producing products made by additive manufacturing.

With technology changing the approaches to finding a solution to a problem, we can not underestimate the impacts of additive manufacturing in the future.

Additive manufacturing in Medicine

3D printing in healthcare emerging applications is becoming more popular in the medical field.

Over two decades ago, Bioprinting became one of the main applications of 3D printing. In today’s medical practices, a 3D printer can be used to create a human liver.

People like Organova (inventor of the first commercial bio-printer – NovoGen MMX), Makoto Nakamura, and scientists from the Tissue Engineering and Regenerative medicine Lab at Columbia University have developed printer models to keep up with this trend.

The applications of additive manufacturing in the medical field are not limited to bioprinting, but it is also used in the production of prostheses; prostheses can be individually adapted to humans and animals.

Also, a 3D bioprinter is easy to be moved closer to the exact body area where doctors are working in the theatre. This is one of the benefits of 3D printing in the medical field.

3D bioprinter is also used to print organs for pre-surgical exercises for practicing doctors and students studying medicines and other related courses.

Today, standard hospitals and clinics are now using 3D printers to meet their patients’ needs.

While the above-mentioned benefits of 3D printing in healthcare are highlighted, there are problems with 3D tech and challenges faced by healthcare companies.

Some of the disadvantages are

- High production cost

- High energy demand

- Production materials are scarce

- It leads to Harmful Emissions

- It can increase Plastic pollution

Additive manufacturing applications in the automotive industry

Applications of 3d printing in the automotive industry have increased rapidly in the last two decades. We now have 3D-printed automobile parts.

Additive manufacturing is now changing how we move and transport things. The benefits of 3D manufacturing are felt in marine, aerospace, and land transportation means.

Whether in aerospace, automotive, or shipping, companies are looking for ways to manage their time and money.

Since it costs so much, for example, to transport materials into space, authorities, airlines, and transport companies are looking for ways to minimize the high transport costs.

To help to reduce the high costs, additive manufacturing is being relied upon. It makes it possible to optimize the topology so that weight can be optimized without having to sacrifice load capacity.

The advance of 3D printing in the field of metal spare parts also allows technological and pragmatic advances in the automotive industry.

In the current state of 3d printing in the automotive industry, we now have cars or ships that are manufactured using a 3D printer.

Additive manufacturing in the construction industry

The application of additive manufacturing in the construction industry has not just started in recent decades.

Architects and civil engineers have been using CAD programs to design and construct buildings on their computers for quite some time now.

With the advent of additive manufacturing 3D printing, many construction companies can now use this technology to build models.

With 3D printing, architects can now develop building models with many details. More engineers are now finding it easy to use this technology since they are already used to CAD programs long before the advent of 3D printing.

3D printing can be used to deliver building construction within a short time and with fewer human resources.

For example, Apis Cor (the first company in the US that developed specialized equipment for 3D printing) completed a 3D-printed house within 30 hours.

The company used 3D machines to complete this project where their movable arms helped to distribute the concrete evenly.

Other examples are the printing of a metal bridge in Amsterdam. Even the American Space Agency is working towards using 3D printing to design buildings on the moon and Mars.

Additive manufacturing in art & design

3D printing technologies are increasingly used in the art & design field.

Professional artists across the globe now incorporate 3D printing into their art design.

This is because additive manufacturing helps artists actualize their weird imaginations

With this technology, artists will change the scope of art engineering in the future. Already, we can say that the future of digital art is already here.

Examples of the impacts of 3D printing are the dress collections by Danit Peleg, jewelry by Diana Law, and even the production of chocolates of different shapes by Dinara Kasko.

Other areas of the applications of AM

Additive manufacturing is finding its way into almost all sectors of the economy.

It is one of the technologies that now influence our entire society as it facilitates the development of new products, personalizing products, and meeting some very specific needs.

In aerospace, AM is now being explored in many space research. Additive manufacturing is already used successfully in building new satellites or a lunar station.

This will make it easy to send elements into space with much less weight.

Conclusion

3D printing offers different applications across several industries. It offers efficient solutions in robotics, innovations in sports, health, construction, Arts and design, etc.